Silicone Grease is refined from silicone oil as a base oil thickening inorganic thickener, with good waterproof sealing, waterproofing, solvent resistance, and anti creepage performance.

It does not corrode metals and has good adaptability to rubber.

It is used for waterproof sealing and lubrication in the bathroom equipment, sealing rings, and electronic and electrical industries.

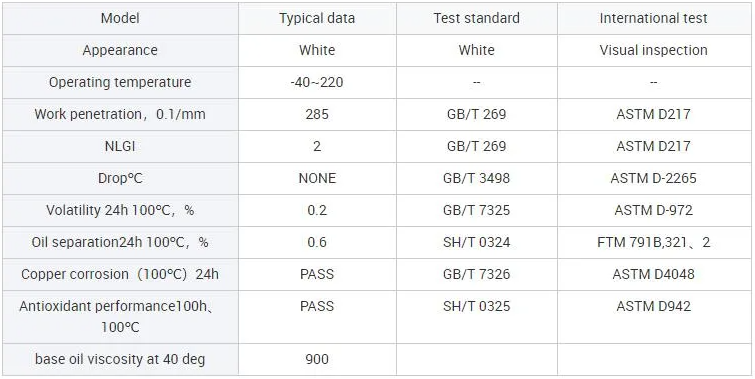

Performance characteristics:

1.Excellent thermal conductivity and stability in use, good resistance to high and low temperatures

2.Water resistant, non curing, and non corrosive to metal materials in contact (copper, aluminum, steel)

3.Extremely low volatilization loss, non drying and non melting, good material adaptability, and wide temperature range for use (-50 +250 ℃)

4.Non toxic, odorless, non corrosive, with stable chemical and physical properties

Instructions:

1. Before adding grease, ensure that the surface of the lubricated parts is clean and dry, and ensure the cleanliness of the grease injection process.

2. It is prohibited to mix different brands of lubricating grease.

3. Pay attention to the replacement cycle and management of the usage process, and the amount added should be appropriate

The company has set up 2 professional laboratories to continuously and customize products per clients’ requirements. Doctors: 2 people,Senior engineers:12 people.

The company is constantly building new factories, it has 5 production lines,more than 150 workers.

The products produces in each batch undergo , raw materials inspected before producing, working in process and finished goods is inspected before shipping.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Dachegn will serve you wholeheartedly.