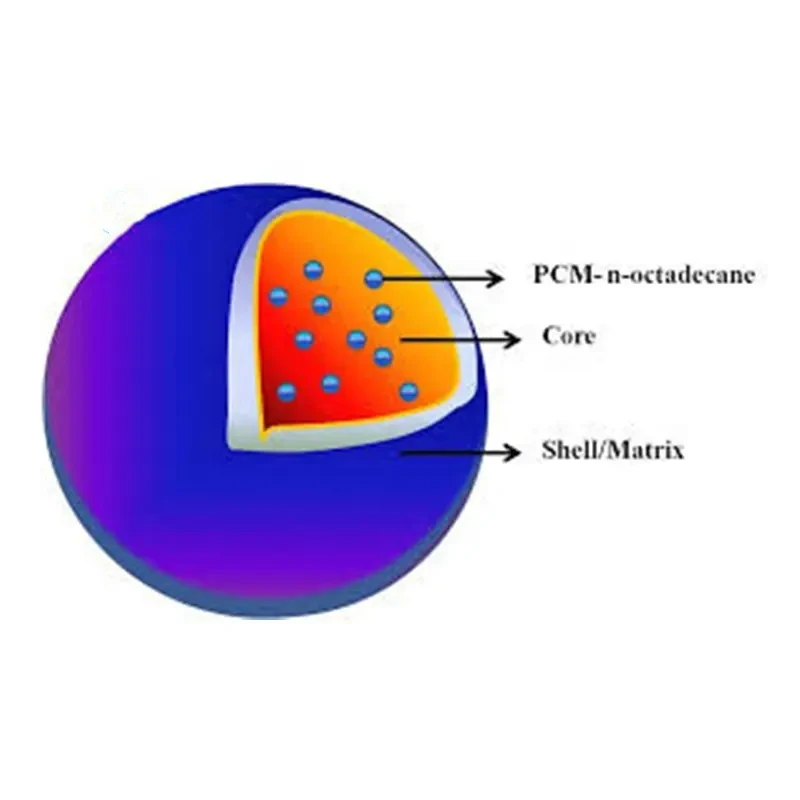

The PCM series of microencapsulated phase change materials encapsulate phase change materials with high energy storage density in micrometer sized capsules, maintaining a flowable powder state throughout the material's phase change process. Microcapsule phase change materials absolutely do not contain toxic substances such as formaldehyde and have been certified by the EU Rohs through SGS testing. They can be widely used in fields such as memory cotton, textiles, building energy conservation and temperature control.

Phase change material (PCM) is a substance with a high heat of fusion which, melting and solidifying at a certain temperature, is capable of storing and releasing large amounts of energy. Heat is absorbed or released when the material changes from solid to liquid and vice versa; thus, PCMs are classified as latent heat storage (LHS) units.

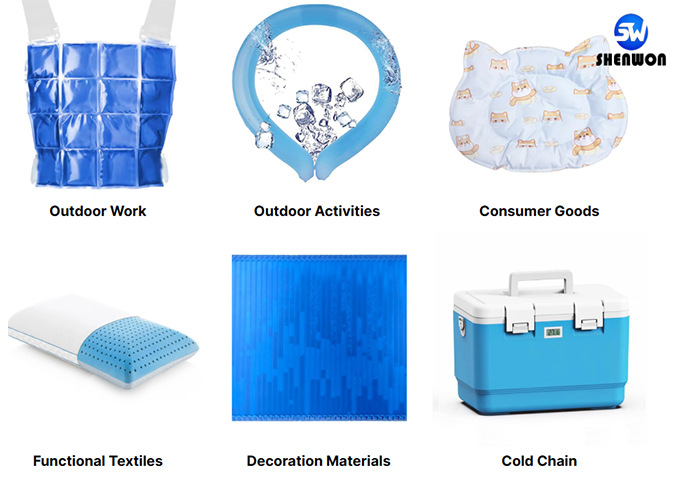

Phase Change Materials have been widely used in human life, which becomes one of the best energy saving and environmental protection carriers.

Application in residencial areas

Phase change materials are widely used in residential rooms especialy elderly room, because PCM can reduce the temperature difference and maintain the stability of indoor temperature, providing a comfortable living environment for the elderly. For example, the PCM can absorb and release heat, automatically adjust according to the change of indoor temperature, keeping the indoor temperature stable.

Application in stand-alone buildings

For stand-alone buildings, phase change materials can be used to improve the energy efficiency and comfort of the building. The phase change material can be used in the exterior wall, roof and ground of the building to absorb and release heat and keep the temperature of the building stable. In addition, the phase change material can also be used to make products such as intelligent curtains and intelligent glass, and realize the automatic opening and closing of curtains or glass by adjusting the phase change temperature of the phase change material, and then adjust the indoor light and temperature.

Application in warehouse

For warehouses, phase change materials can be used to maintain temperature stability in the warehouse. When the external temperature changes, the phase change material can absorb or release heat to keep the temperature in the warehouse in a constant range. This helps maintain the quality and performance of items while reducing the impact of temperature fluctuations on items. In addition, the phase change material can be used to adjust the humidity in the warehouse, helping to keep the humidity in a stable range.

Latent heat storage can be achieved through liquid→solid, solid→liquid, solid→gas and liquid→gas phase changes. However, only solid→liquid and liquid→solid phase changes are practical for PCMs. Although liquid–gas transitions have a higher heat of transformation than solid–liquid transitions, liquid→gas phase changes are impractical for thermal storage because large volumes or high pressures are required to store the materials in their gas phase. Solid–solid phase changes are typically very slow and have a relatively low heat of transformation.

| Chemical Composition | Phase change nanomaterials |

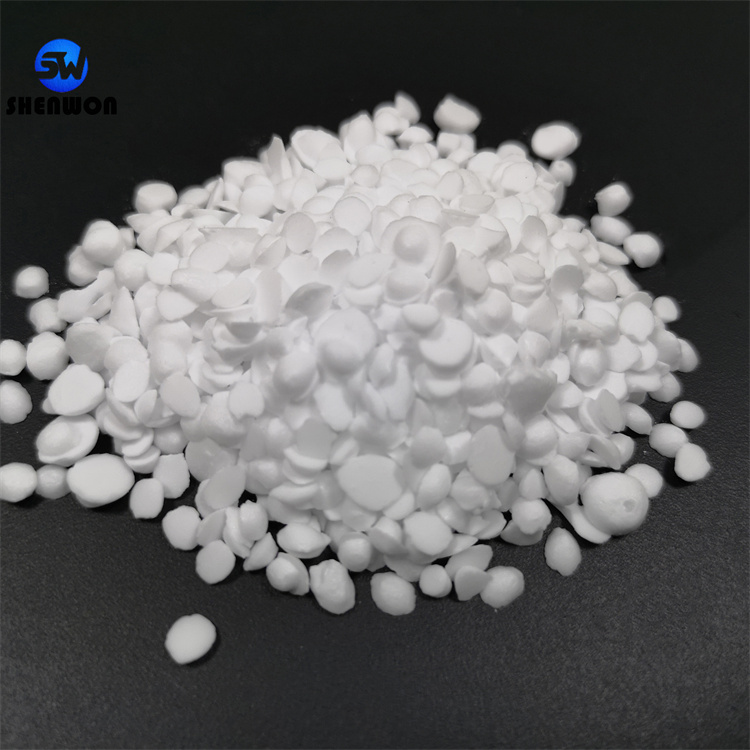

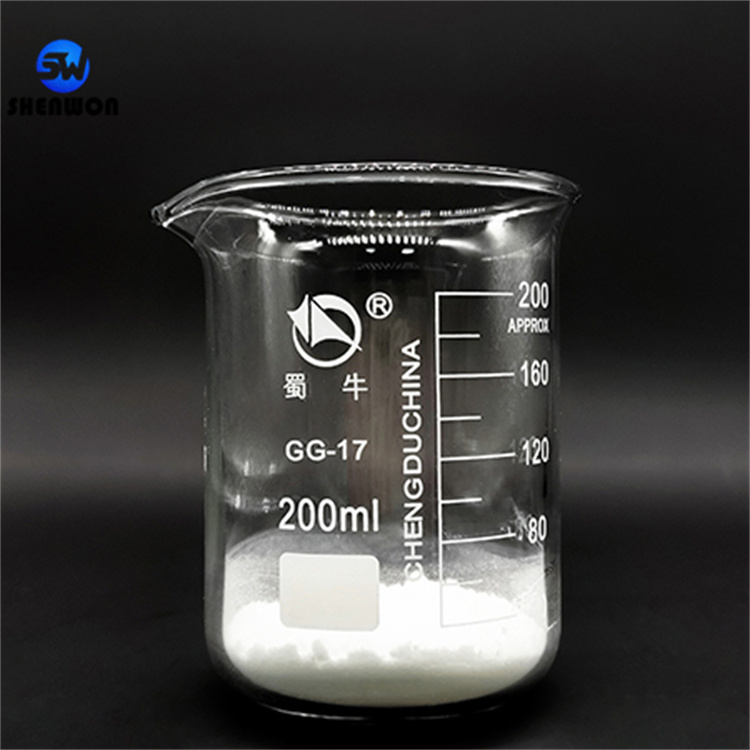

| Appearance | Milky white liquid,powder,granular |

| Shell | Polyacrylate (approximately 15% wt) |

| Core material | n-octadecane (approximately 85% wt) |

| Phase transition temperature | 29.0 ± 1.5 ℃ (DSC method, melting point) |

| Enthalpy value | 180.0J/g (DSC method) |

| Solid content | 30 ± 1% |

| Ionic type | Anion |

| PH value | 6-8 |

| Decomposition temperature | about 230 ℃ |

| Stability | Store at normal temperature and avoid freezing. The temperature should not be lower than 10 ℃. |

| Compatibility | Stable and effective within the pH range of 3-8. May cause |

The company has set up 2 professional laboratories to continuously and customize products per clients’ requirements. Doctors: 2 people,Senior engineers:12 people.

The company is constantly building new factories, it has 5 production lines,more than 150 workers.

The products produces in each batch undergo , raw materials inspected before producing, working in process and finished goods is inspected before shipping.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Dachegn will serve you wholeheartedly.