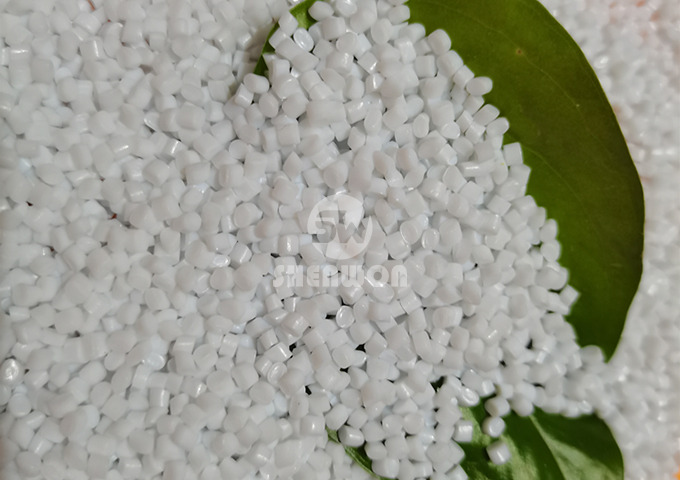

PET Resin is cream or pale-yellow crystal, with smooth and shiny surface. Resistance to creep deformation, fatigue resistance, abrasion resistance and dimensional stability are perfect. Small wear and tear but high hardness, its toughness is the largest in thermoplastic. The electrical insulation of PET is perfect and little be affected by temperature, however, poor corona resistance. PET is non-toxic, weather resistance, and anti-chemical stability is very good. PET is low water absorption, resistance to weak acids and organic solvents. Intolerance of hot water immersion and alkali.

Feature:

1. Oil resistant, fat resistant, acid resistant, alkali resistant, resistant to most solvents.

2. Excellent resistance performance of high and low temperature.

3. Non-toxic, tasteless, health and safety.

4. Transparent, UV blocking, good glossiness.

1. Various types of food, medicines, non-toxic sterile packaging materials; Textiles, precision instruments, electrical components, high-grade packaging materials; Tapes, videotapes, film, computer floppy disk, metal coating and the substrate such as photographic film; Electrical insulation materials, capacitor film, flexible printed circuit boards and membrane switch and other electronics and machinery.

2. Package bottle: From the initial development of carbonated beverages to the present beer bottles, cooking oil bottles, condiment bottles, medicine bottles, cosmetic bottles.

3. Electric products: Manufacture of connectors, coil winding tube, integrated circuit case, capacitor, transformer enclosure, TV accessories, tuners, switches, timer cover, auto fuses, motor bracket, and relays.

4. Auto Parts: Such as distribution panels cover, ignition coils, valves, exhaust parts, distributor cap, casing measuring instruments, small electric motor housings, etc., can also be a good use of PET coating, surface gloss and rigidity, making the car exterior parts.

5. Machinery and equipment: Manufacture of gears, cams, pump housing, pulleys, motor frames and watch parts, can be used as the microwave oven baking, a variety of roof, outdoor billboards and models.

6. PET Plastic molding can be injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, plating, vacuum metallization, printing.

|

Parameter |

Unit |

Grade 1 |

Grade 2 |

Grade 3 |

|

I.V. |

dL/g |

0.800±0.020 |

0.840±0.020 |

0.860±0.020 |

|

DEG |

% |

1.40±0.30 |

1.40±0.30 |

1.10±0.30 |

|

-COOH |

mmol/kg |

≤35 |

≤35 |

≤35 |

|

AA |

ug/g |

≤1.0 |

≤1.0 |

≤1.0 |

|

Color value,L |

/ |

≥80 |

≥80 |

≥70 |

|

Color value,B |

/ |

≤1.0 |

≤1.0 |

≤1.0 |

|

Powder |

mg/kg |

≤100 |

≤100 |

≤100 |

|

Melting point |

℃ |

≥245 |

≥246 |

≥249 |

|

Density |

g/cm3 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

|

Moisture |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

Ash |

% |

≤0.08 |

≤0.08 |

≤0.08 |

PET IV 0.80 +/- 0.02 - For Water Bottle / PET Sheet.

PET IV 0.82 or 0.83 +/- 0.02 - For Edible Oil Bottle.

PET IV 0.84 or 0.85 0r 0.86 +/- 0.02 - For CSD Bottles.

PET IV 0.76 or 0.78 +/- 0.02 - For Hot Fill Bottle / Water Bottle.

The company has set up 2 professional laboratories to continuously and customize products per clients’ requirements. Doctors: 2 people,Senior engineers:12 people.

The company is constantly building new factories, it has 5 production lines,more than 150 workers.

The products produces in each batch undergo , raw materials inspected before producing, working in process and finished goods is inspected before shipping.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Dachegn will serve you wholeheartedly.